We've automated QA checks for enterprises at your production scale

We've automated QA checks for enterprises at your production scale

Scalability

Tangible result case study

Scale and adapt to different operational needs and learn to recognize new patterns over time, making it a versatile tool for various applications.

Real-Time Alerts

Tangible result case study

Enable continuous monitoring of processes, providing instant alerts in case of deviations, allowing for immediate corrective actions.

sustainability

Tangible result case study

Promote greener manufacturing by optimizing resource consumption and minimizing waste, aligning operations with eco-friendly practices.

Two major call-backs due to manual spot checks?

Two major call backs in the last 12 months, mostly due to human based processes relying on manual spot checks. it's not their fault, it was just a matter of time until an error occurred after 500+ checks.

39,000 ZTrack ZTR recalls in Jan, 2025

The affected models-Z720E,Z730M,Z740R, and Z760R-were found to have a defective voltage regulator that could fail during use or storage, leading to engine overheating and posing fire and burn hazards.

However, we understand that this issue primarily stemmed from Kawasaki, and not John Deere.

147,000 recalls on the 1023E, 1025R, 2025R models in Sep, 2024

These compact utility tractors were recalled due to brake linkage components being loose, thus, disconnecting during operation.

Manual inspections relied heavily on visual spot-checks, which couldn't consistently identify subtle torque discrepancies or alignment shifts in the linkage assembly.

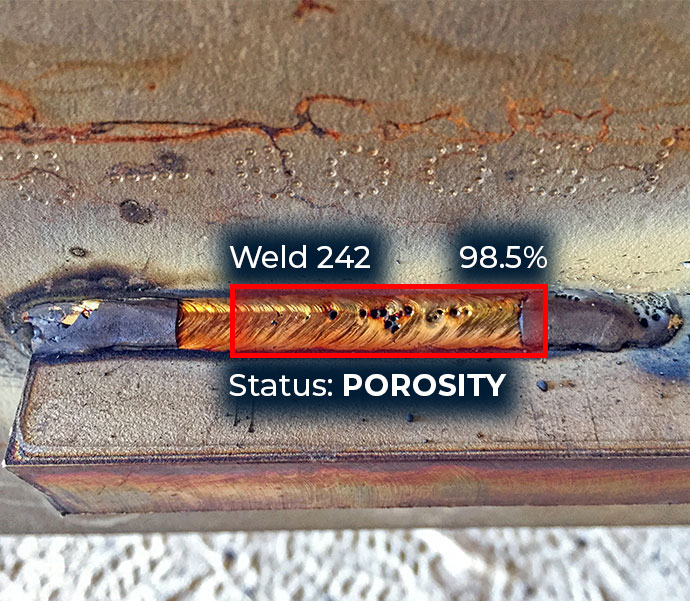

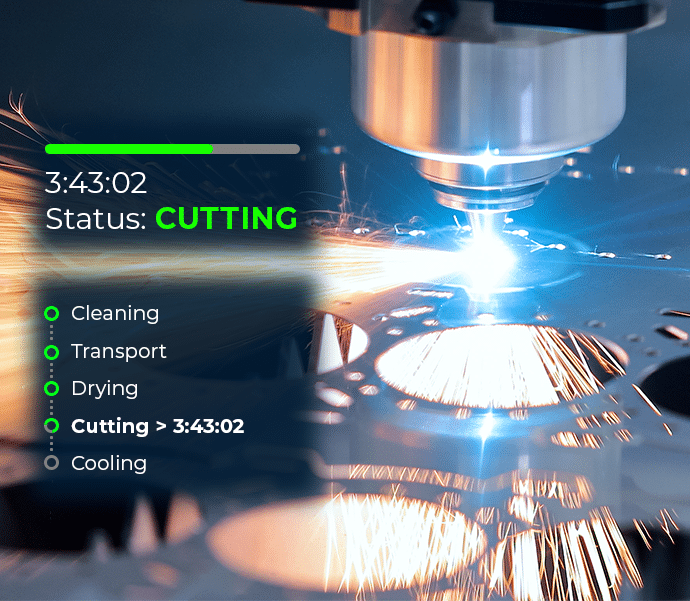

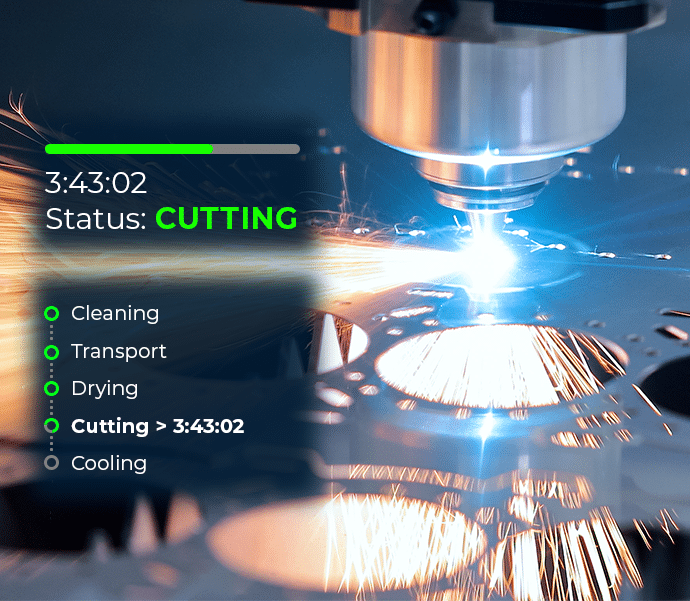

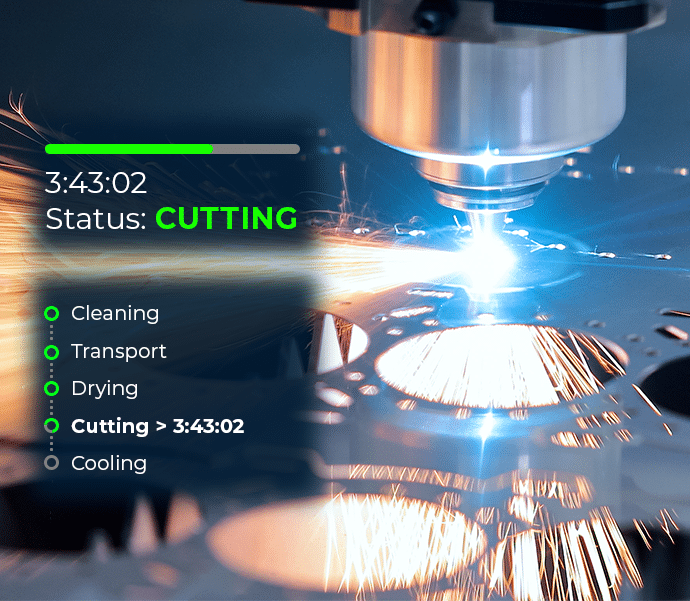

Batch inspection vs. 100% inspections

Detects defects across your entire production line

Matroid learns your ideal scenarios, from screwing in bolts to plane-sized shell connection --> these scenarios are able to be scaled across every camera.

“Perfect scenario” modelling

AI models the perfect scenario, then looks for it in every check

Based on past defect data from your current machine vision cameras, Matroid’s AI builds an ideal visual standard for each component and process.

Thus, flagging subtle deviations from these ideal scenarios—not just defects it was rigidly prompted to find.

Absolute oversight

You know what’s happening, across the entire plant.

Scalable, micro-level detection from a one-time integration across all your existing cameras, add new cameras without machine vision prompting.

STEP 1

Install Matroid’s software once

All your existing cameras connect with Matroid at once, whether they’re normal cameras, or machine vision, within minutes. Alternatively, we provide machine vision cameras for all scenarios.

STEP 2

If you can circle it, you can program Matroid

Easily circle all defects present, or, plug your existing machine vision data into Matroid.

STEP 3

Matroid models perfect scenarios on components

What this means: It doesn’t *just* detect defects, it detects the process itself, how far your bolts are screwed in, if something wasn’t drilled enough. If it finds a mistake in the process --> it is flagged as a defect.

STEP 4

Achieve complete oversight on defects.

Leadership has a single dashboard to oversee all defects, down to what’s common, risk level, priority. Making it easy for QA engineers to quickly create processes around active, re-occurring defects across the entire production line.

Your QA engineer's best friend

Scalability

Enterprise Growth

Scale and adapt to different operational needs and learn to recognize new patterns over time, making it a versatile tool for various applications.

Real-Time Alerts

Alerting & Notifications

Enable continuous monitoring of processes, providing instant alerts in case of deviations, allowing for immediate corrective actions.

sustainability

Minimize Waste

Promote greener manufacturing by optimizing resource consumption and minimizing waste, aligning operations with eco-friendly practices.

It’s quite impressive what the Matroid platform and video analytics gives us. Now Heathrow is able to make adjustments faster and plan more effectively so that our operations do not miss a beat, which helps to ensure a more positive experience for everyone across the terminals

Andy

Innovation Leader at Heathrow

Matroid's computer vision platform is key for ADR's innovation initiatives, the cutting edge deep-learning technology empowers our teams to continuously ensure highly efficient and safe operations across the airport.

Fabrizio

Head of Airport Operations Center

Request A Demo Today

Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo s