How Visual Automation is Revolutionizing Aerospace Quality Control

Matroid | July 8th, 2025

In aerospace manufacturing, there is no margin for error. A single overlooked defect can pose a significant risk to both the manufacturer and future aircraft passengers and crew. However, as aircraft systems become increasingly complex and manufacturing processes become more demanding, traditional quality control methods struggle to keep up.

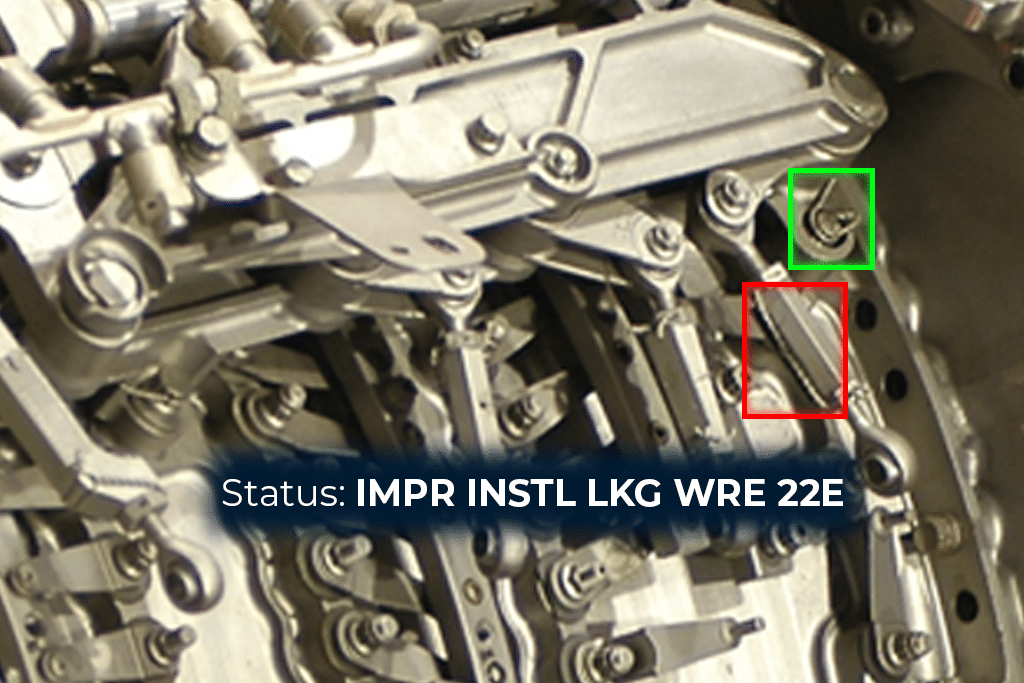

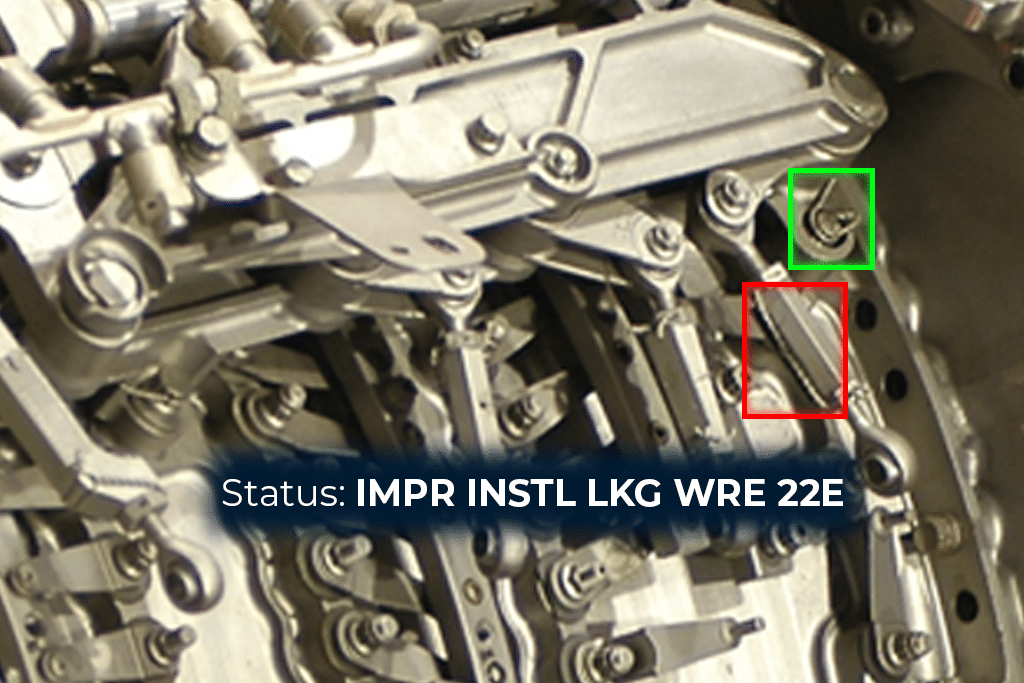

For many industry leaders, the solution lies in visual automation. This technology uses AI and computer vision to inspect parts and assemblies with unmatched speed and accuracy. These systems are transforming how aerospace manufacturers identify and address defects. Even more compelling is that these tools now allow teams to implement AI inspection without writing a single line of code. The result is a smarter, faster, and more scalable approach to quality control that meets the aerospace industry’s evolving needs.

The Challenge: Manual Inspection Under Pressure

For decades, aerospace quality control has relied on skilled technicians performing visual inspections with only limited technology to support the task. While human involvement in quality control is imperative, the integrity of the process can be compromised by human fatigue, attention variability, and the time-consuming nature of manual work.

In high-throughput aerospace production, such as fuselage or turbine blade manufacturing, technicians may be responsible for inspecting thousands of fasteners, seals, or surface finishes each day. Manually checking each piece for the subtlest defect presents a formidable challenge even to the most experienced inspectors. This challenge intensifies when dealing with layered composites, hidden geometries, or tightly packed assemblies where visibility is limited.

The consequences of missed defects in aerospace can be dire. Production delays and reworking a defective piece of equipment demand significant investments of time, money, and manpower. More importantly, faulty equipment can lead to safety-critical failures that could prevent the finished aircraft from ever taking to the air.

The Solution: Visual Automation

Visual automation refers to the use of AI-powered computer vision systems to automatically inspect and analyze visual data from manufacturing processes. At the core of these systems are high-resolution cameras paired with deep learning models trained to recognize patterns, anomalies, and defects across various materials and components. By integrating directly with production lines or inspection stations, these systems provide real-time feedback and generate a consistent, objective assessment of product quality.

AI-Powered Quality Control: Faster, More Accurate, Auditable, and Scalable

One significant advantage of visual automation is speed. AI-based systems can process and analyze images in a fraction of the time human inspectors require while maintaining consistent performance over time. This drastic speed increase ensures that the production line continues to operate smoothly without allowing any defects to pass through.

But even more important than speed is accuracy, which visual automation improves significantly. AI models can be trained to detect defects that are too small or too subtle for the human eye to perceive. They can also recognize patterns that indicate emerging issues, such as the early signs of tool wear or process drift, allowing for preventive action before defects multiply.

AI models also have the distinct advantage of creating their records in real time. This eliminates the time spent waiting for inspectors to compile and submit logs of their work. An AI-powered visual automation system creates auditable records that meet legal requirements with no additional effort required.

Finally, visual automation scales effortlessly. Whether a manufacturer is producing 10 units per day or 10,000, these systems can handle the volume without compromising quality. Multiple inspection points can be added across a facility, and models can be deployed remotely or updated across sites with minimal effort.

No-Code Deployment: Making Visual Automation Accessible to All

One of the most exciting developments in visual automation is the rise of no-code platforms. In the past, implementing computer vision required teams of software engineers and data scientists to develop custom models and code complex workflows. This barrier could put advanced AI inspection out of reach for many aerospace companies.

Matroid’s no-code computer vision solution eliminates that hurdle. Our system uses intuitive interfaces to allow quality control teams to upload images, label defects, train models, and deploy inspection systems without ever writing a single line of code. This approach enables companies to get their visual automation systems up and running sooner and at a significantly lower cost than higher-level AI systems. Most importantly, our system turns AI model training from an intimidating process to a simple part of the workday.

This democratization of AI is especially valuable in the aerospace industry, where subject matter expertise is critical but in-house AI talent may be limited. By making AI accessible to non-programmers, visual automation platforms allow quality teams to directly apply their domain knowledge and adapt inspection systems as needed.

Visual Automation: The Next Step in Aerospace Manufacturing Quality Control

Matroid’s visual automation is not just a technological upgrade. It represents a paradigm shift in how aerospace manufacturers approach quality control. By combining the speed and precision of AI with the simplicity of no-code platforms, Matroid’s systems enable aerospace industry leaders to meet stringent legal standards without falling behind the competition.

In a sector where the smallest defect can have the largest consequences, the ability to catch issues early and often is invaluable. With visual automation, aerospace companies can ensure they meet the highest standards of safety and performance, without compromising efficiency or scalability. The future of aerospace quality control is here, and it is visual, intelligent, and remarkably easy to deploy.

To see Matroid’s visual automation system in action and learn what it can do for your workplace, get in touch with us for a one-on-one demo today.

Building Custom Computer Vision Models with Matroid

Dive into the world of personalized computer vision models with Matroid's comprehensive guide – click to download today