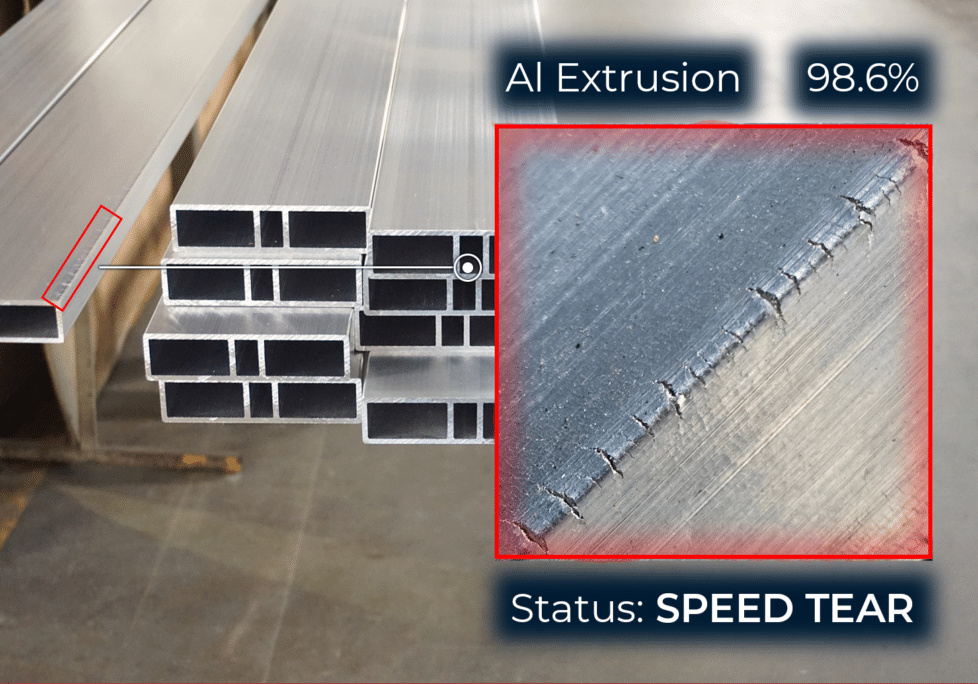

Scale Beyond Manual QA with Advanced Computer Vision

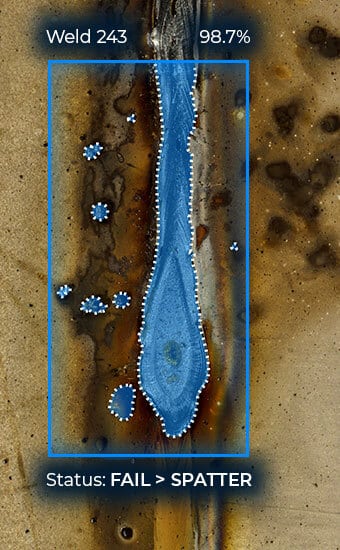

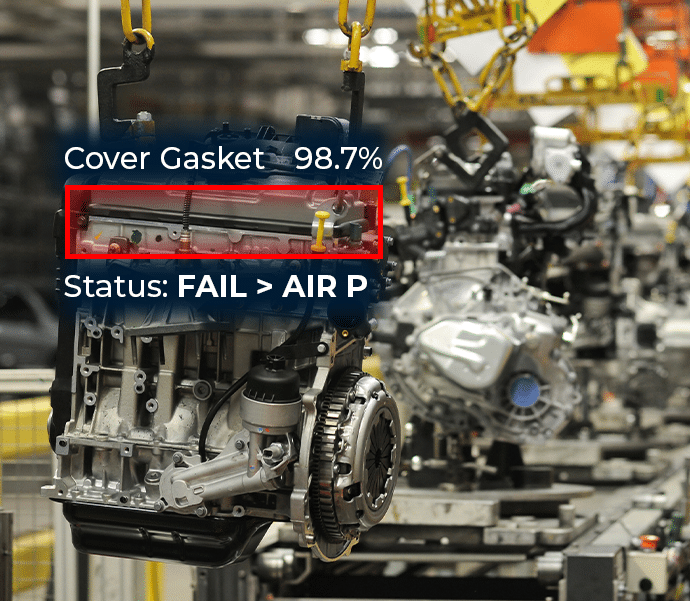

Matroid equips industrial manufacturers with real-time, automated visual inspection that scales across your lines, sites, and processes—reducing manual spot-checks and giving your team superhuman defect detection.

FAIL

Bolt Torsion

We’ve automated QA checks for enterprises at your production scale:

Whats inside the 30-minute demo?

Got a defect that’s hard to catch by your lineworkers, or hard to program with machine vision? This call will highlight your biggest QA detection issue. We’ll send the image/video of Matroid’s AI detecting your defect back within 48hrs.

STEP 1

Send us an image / video of your most difficult defects

Send us any defects that you’re having trouble catching, especially if it's hard to program with Machine Vision cameras, or see with human eyes.

STEP 2

We’ll deploy Matroid onto your image/video

Provide us instances where defects cause problems, and Matroid can detect the moment it happens. (Eg. A fire)

STEP 3

Still don’t believe us? We’ll come to your plant.

If you still don’t believe we can detect your most difficult defects within hours, we’ll come to your plant to demonstrate Matroid in real life.

PREVENT YOUR NEXT RECALL

Manual spot checks are costing you millions.

In an industry where a single recall can mean losses in the tens of millions, relying on manual inspection is a risk you can't afford to take.

How Matroid prevents defects

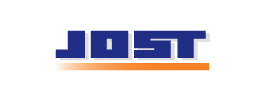

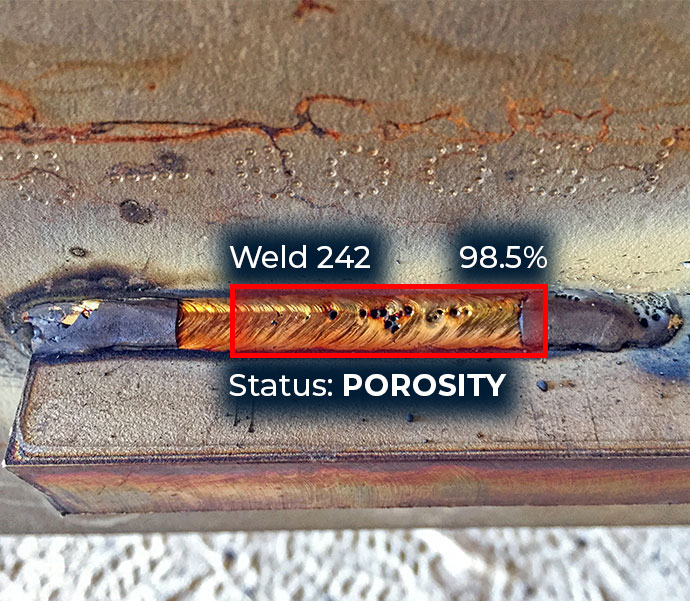

Matroid’s AI scales across all locations, scenarios, and cameras—without needing batched data or existing setups. It learns from known defects to provide real-time, scalable checks for both known and potential unknown defects.

Detects defects across your entire production line

Matroid learns your ideal scenarios, from screwing in bolts to plane-sized shell connection --> these scenarios are able to be scaled across every camera.

How it works

Matroid’s artificial intelligence goes beyond just scanning defects

Install Matroid’s AI once, it connects with all your existing Machine Vision cameras, now it has intelligent detection beyond it’s static prompting.

STEP 1

Install Matroid’s software once

All your existing cameras connect with Matroid at once, whether they’re normal cameras, or machine vision, within minutes. Alternatively, we provide machine vision cameras for all scenarios.

STEP 2

If you can circle it, you can program Matroid

Easily circle all defects present, or, plug your existing machine vision data into Matroid.

STEP 3

Matroid models perfect scenarios on components

What this means: It doesn’t *just* detect defects, it detects the process itself, how far your bolts are screwed in, if something wasn’t drilled enough. If it finds a mistake in the process --> it is flagged as a defect.

STEP 4

Achieve complete oversight on defects

Leadership has a single dashboard to oversee all defects, down to what’s common, risk level, priority. Making it easy for QA engineers to quickly create processes around active, re-occurring defects across the entire production line.

Your QA engineer's best friend.

Engineers can finally focus on optimizing their process.

Instead of your QA team spending 6-8hrs per day watching paint dry, they can finally let Matroid detect all forms of issues in real-time --> get it sent to leadership to quickly devise a plan to fix it across all facilities.

Batch inspections vs. 100% product line inspections

Traditional batch inspections check only a fraction of products, risking defects slipping through. Matroid’s AI inspects every single item in real-time, ensuring 100% defect detection at scale.

Every defect, notified in minutes, not months

Matroid’s AI alerts your team instantly, so you can stop defects upstream before they impact production downstream. Easily build processes around constant defects.

Schedule a demo

We won’t bore you with a pitch deck. We’ll actively use Matroid to detect issues your current process can’t find within 48 hours.