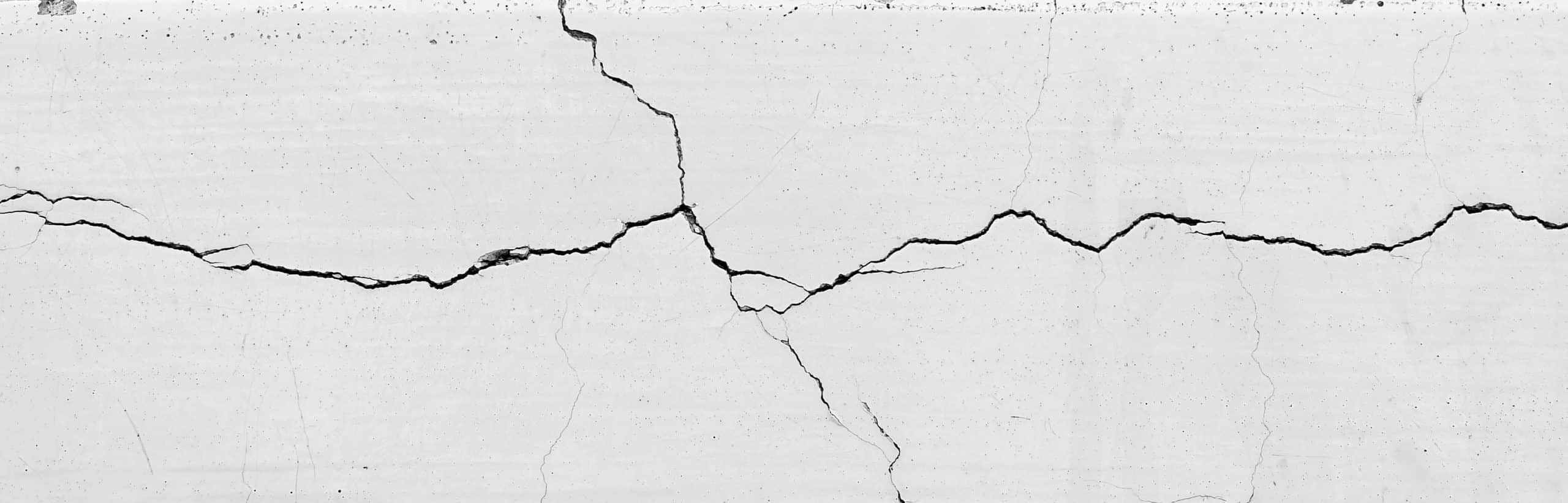

Problem: Cracks are dangerous and undermine structural integrity in both Manufacturing and Critical Infrastructure

Cracks are one of the earliest indications of degradation of a structure or manufactured product. Manual inspection is currently the most common method for crack detection.

During manual inspection of a structure, an image of the crack is prepared manually, and the conditions of the damage are noted. This manual approach depends on the Subject Matter Expert’s knowledge and experience and can lack objectivity in the quantitative analysis.

In regards to manual inspection of manufactured parts, again, this is reliant on the SME’s knowledge and experience.

If a crack is missed or misjudged, it can lead to catastrophic consequences in both manufacturing and in structural integrity.

Matroid’s solution: Crack Detector

To prevent situations like these, Matroid has created a Crack Detector. This detector can be used as a baseline for understanding what is possible for creating a specific crack detector using Matroid.

Automated inspection can be performed with a Matroid detector, an “automated pair of eyes” that leverages state-of-the-art computer vision to find objects of interest in visual media.

Using Matroid’s Studio, you can train detectors with practically any dataset. For this project, we took a dataset of various different types of cracks and uploaded them into Matroid Studio. After the images were uploaded, we then trained the detector with the press of a button. Within minutes, we had a detector that could identify the presence of a crack within any type of visual image. With less than an hour of work we had a generic crack detector that would have otherwise taken weeks or months to train from scratch.

Matroid’s solution: Tracking cracks with Similarity Search

Beyond creating the initial detector with the Matroid Studio, Matroid can also help manage crack detection data with Similarity Search, a feature that enables millisecond level visual similarity search across archived or live media at scale. This is particularly useful for tracking structural cracks over time to see how they have progressed and make estimates on when maintenance might be required. It can also be used to search for similar cracks on other surfaces or structures, in order to get a sense of which types of issues are most common.

In this example, we can identify the most visually similar cracks across multiple results.

Matroid’s solution: Real time detections for better and faster crack inspections

Matroid can also help monitor for cracks in parts manufacturing in real-time with Stream Monitoring. With Stream Monitoring, you can connect your ONVIF compatible cameras or any other visual sensor, monitor them with your detectors, and set up API and email based alerting for when objects or defects of interest are detected. For example, a standard CNC machine with a connected camera can inspect parts automatically as they are being created, and only trigger an alarm when a crack defect is detected. This eliminates the need for manual inspection of parts, allowing for SMEs on site to work on other parts of the manufacturing process, and simply verifying alarms when they occur.

Crack detection is one of many examples of Matroid helping automate visual asset inspection in manufacturing and industrial IoT, improving asset longevity and productivity, whilst minimizing maintenance costs. To learn more about how Matroid could help you say no to cracks, get in touch with us today.

Building Custom Computer Vision Models with Matroid

Dive into the world of personalized computer vision models with Matroid's comprehensive guide – click to download today