Improve Automotive Manufacturing with Worker Augmentation AI

Matroid | June 4th, 2025

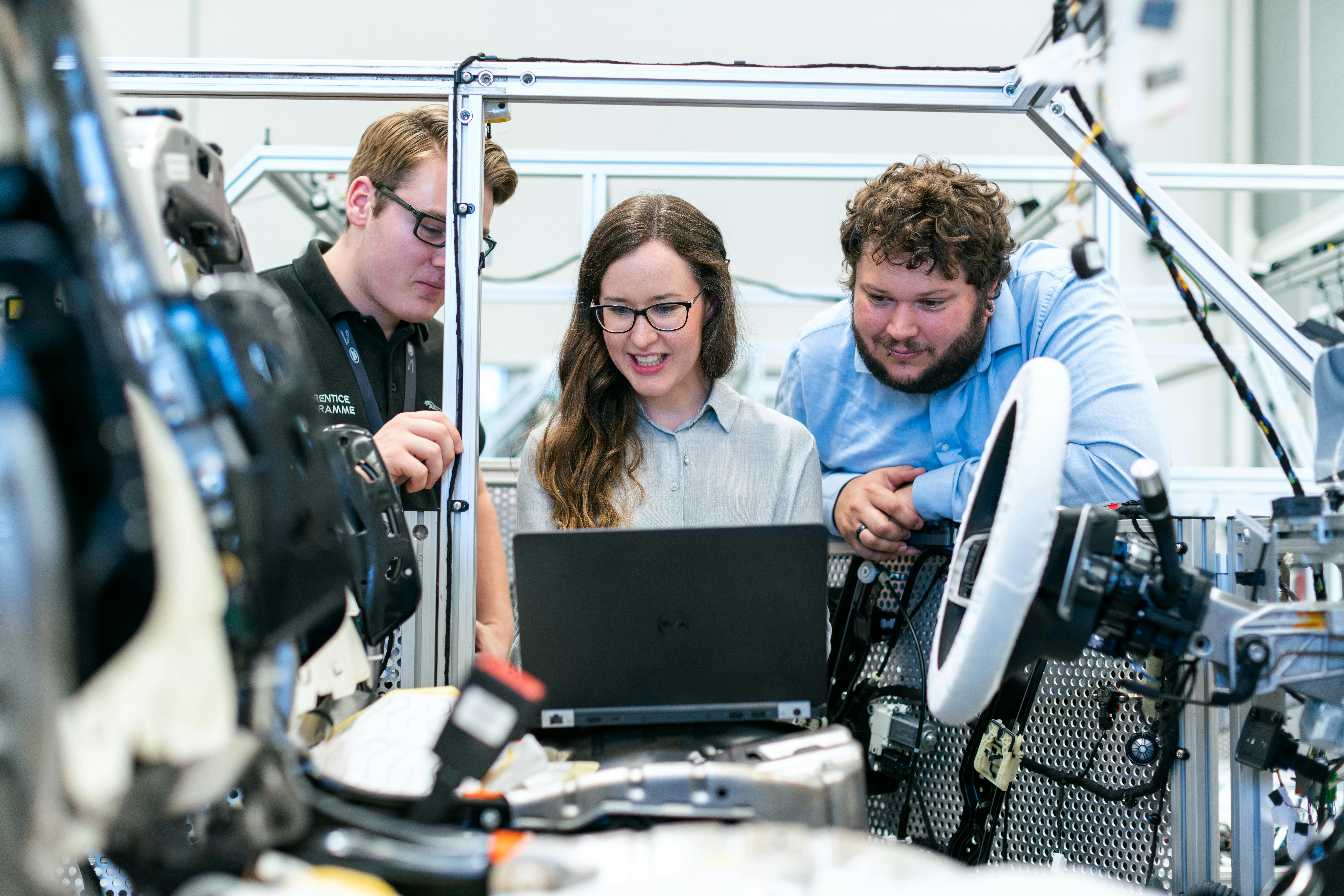

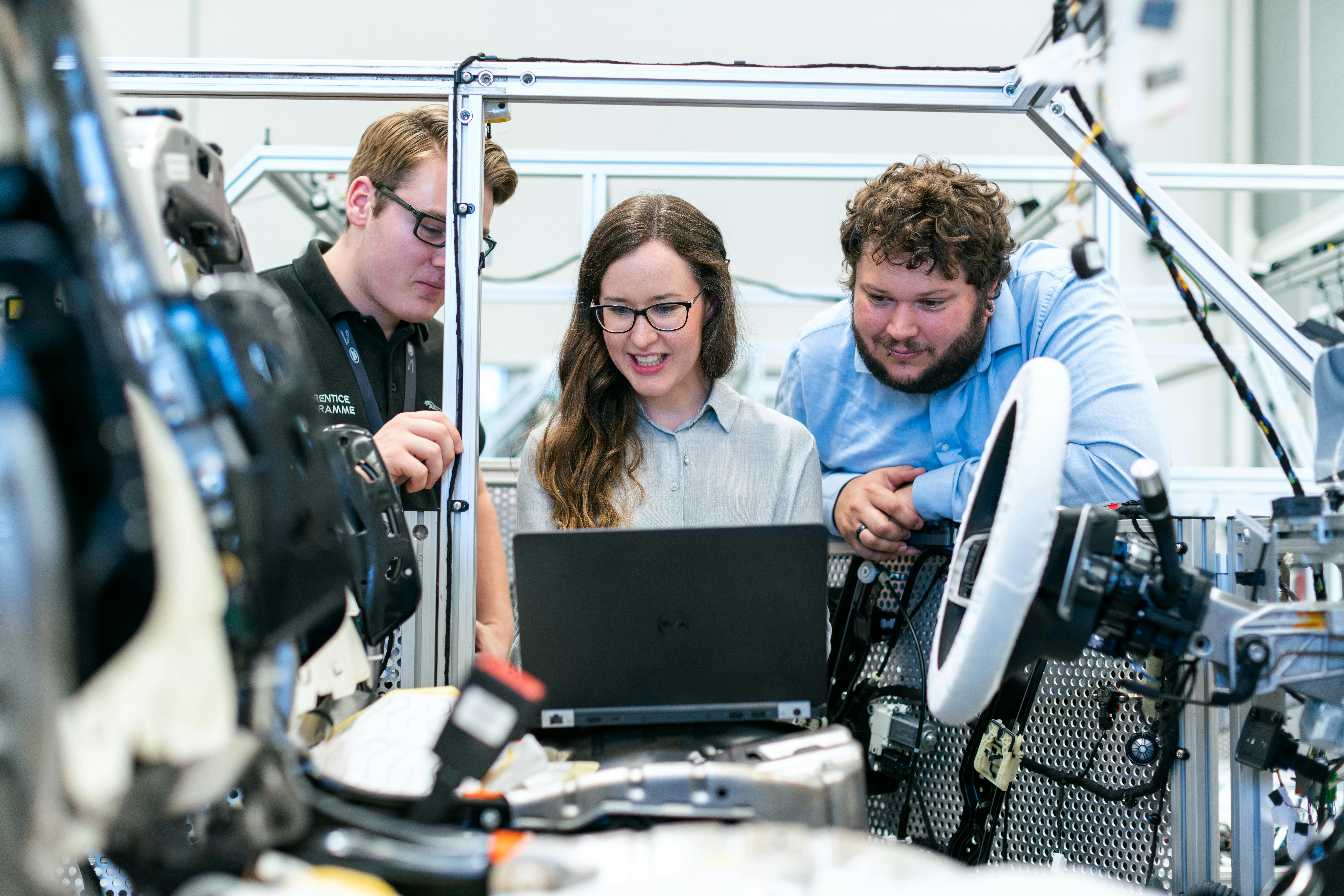

What happens when you combine human expertise and Matroid’s no-code computer vision? If you’ve ever wondered how worker augmentation AI can be used in the automotive manufacturing and production field, this article illustrates some of the many ways that AI is helping workers see more and do more.

What is Worker Augmentation AI?

Worker Augmentation AI brings together human expertise and Matroid’s no-code computer vision systems to give every operator “smarter vision” on the assembly line. By plugging into existing camera networks,

Matroid inspects, tracks and alerts teams in real-time whenever production veers from the standard procedure. Whether it’s misaligned sub-assemblies to blemishes before painting, workers can correct issues instantly, greatly minimizing scrap rates while maintaining and maximizing uptime, without the need to write a single line of code.

How Does Matroid’s AI-Driven Quality Control Help?

Mercedes, Yazaki, Jost and other leading OEMs trust Matroid’s AI-driven solution at every stage of vehicle or part production. With a worker-centered approach, the process can handle all types of production, including:

Detecting Defects

Matroid’s comprehensive system can spot and alert team members to defects ranging from surface-level blemishes to misalignments, and even foreign objects. This rapid detection helps protect brand reputation while minimizing scrap.

Greater Production and Cycle Time Efficiency

Team leaders can now monitor cycle times in real-time, keeping production levels high while also receiving alerts when deviations are detected. This helps keep machinery running while minimizing downtime and allows operators to make instant corrections as necessary.

Validate Builds and Components

Using computer-assisted vision, team members can verify that each part has been assembled according to its exact specifications. If dimensions or cleanliness fall outside of set norms, the system can alert responsible team members.

Eliminate Reworks

Team members can uncover the root cause of defects while reducing downtime, letting staff focus on more value-added or strategic tasks instead of having to handle reworks or manual re-inspections.

Sustainability and Waste Reduction

By catching defects early and optimizing resources, team members can help cut down on scrap and support the company’s environmental and sustainability goals.

Facing the Biggest Automotive Challenges

Matroid’s AI-enhanced computer vision works alongside workers to help improve processes across the production line. For example:

Powertrain Precision

Matroid’s system for automotive manufacturing can spot assembly flaws in engines, transmissions and control systems to keep all necessary parts in line with SOPs while keeping production running at the highest levels.

Flawless Stamping

Screen stamped metal parts for holes, splits or tears, making sure that only perfect components pass inspection.

Premium Welds

Matroid handles spot inspections, MIG/TIG laser and seam welds, checking for burnthrough, misalignments, porosity and spatter, guaranteeing weld integrity without the need for manual reworks.

Paint Flaws

Scan painted surfaces for scratches, drops and runs to deliver a flawless finish on every vehicle body.

Plastic Defect Detection

Catch short shots, missing clips and molding issues in dashboards and trim, keeping assembly streamlined while reducing cycle times.

Part and Final Assembly

Automate checks for sub-assembly alignment, sensor functionality, cleanliness and final component installs while supporting error-free assembly and testing.

Unlocking Significant ROI

Manufacturers who take advantage of Matroid’s worker augmentation AI enjoy a number of returns on their investment, including faster cycle times and more efficient workflows. Quality improves measurably, with a higher yield of defect-free products, which ripples out to brand reputation and quality. With fewer reworks and less waste, the business saves money while staying compliant with SOPs and regulations.

Rapid Deployment with No-Code, Pre-Made Detectors

Because Matroid’s advanced systems require no coding, you can create, train and deploy detectors in minutes with zero programming experience or know-how. Take advantage of Matroid’s extensive library of pre-made, ready-to-use detectors for stampings, weld finishes and more, drastically cutting time-to-value.

What’s more, Matroid’s detectors work with any camera system, including those on-site, in the cloud or at the edge, to AI-augment workers across the entire production floor.

Getting Started with Matroid AI Augmentation

Worker augmentation AI bridges the gap between human capacity and machine learning by embedding AI-driven oversight directly into existing workflows. By taking advantage of Matroid’s no-code platform, operators can instantly gain greater visibility into defects which allows for immediate correction before the problem escalates into costly downtime or machine maintenance.

What’s more, tightly integrating AI systems with human abilities preserves the operator’s central responsibilities and role, while making their impact even more important as part of the overall quality control process. In essence, each worker becomes a highly-effective quality monitor.

But Matroid’s solutions are about more than just detecting defects. These solutions have been shown to drive measurable gains in efficiency across every stage of production. With the automated inspection of everything from stampings to welds, to plastic components to paint finishes, workers can focus on higher-value tasks while cutting costs and scrap rates. Detailed analytics give teams the ability to address recurring issues, creating a continuous cycle of improvement without adding more complexity into existing operations.

Rapid deployment is a hallmark of Matroid’s solution. For automotive manufacturers looking to get started with our powerful, comprehensive AI computer vision system, we invite you to browse our library of pre-made detectors. Thanks to our built-in hardware-agnostic integration, it’s possible to set up inspections in minutes – enabling truly plug and play models that work with existing and established production lines and greenfield projects.

Matroid’s solutions not only flag visible defects but also pave the way for greater operator intelligence. Our computer vision-assisted quality control continues to improve through data collection and pattern recognition. These continual improvements help optimize processes at every stage of fabrication while enabling predictive maintenance.

Now is the time to achieve true zero-defect production together with improved sustainability while maintaining a competitive edge in the automotive industry. As the market becomes more exacting, companies that embrace the benefits of AI will be the ones who stand to gain the highest ROI. Contact us today to learn more.

Building Custom Computer Vision Models with Matroid

Dive into the world of personalized computer vision models with Matroid's comprehensive guide – click to download today