AI-Powered Quality Control for Chemicals & Materials Manufacturing: Reducing Defects & Waste

Matroid | June 24th, 2025

Computer Vision Reduces Defects and Waste in Chemical & Materials Manufacturing

Chemical and materials manufacturers increasingly turn to computer vision to tackle persistent challenges like product defects, process inconsistencies, and unnecessary waste. Those responsible for manufacturing operations or quality control are under constant pressure to keep lines moving, meet compliance standards, and reduce costs. The rise of AI-powered computer vision offers a practical way to accomplish all those goals while paving the way for more sustainable, data-driven manufacturing.

The growing adoption of computer vision is revolutionizing quality, safety, cost, and sustainability in materials and chemical production, including industrial coatings. From surface inspections to real-time contamination alerts, more innovative vision systems are building better processes and stronger businesses.

The Evolution of Computer Vision in Manufacturing

Computer vision isn’t just about sticking cameras on your production line and calling it a day. Today’s systems combine high-resolution cameras with machine learning algorithms that spot issues far earlier and more consistently than humans. They can flag a scratch on a coating, a color deviation in a polymer, or the subtle onset of contamination in a batch vessel. This happens in real-time, giving operators instant feedback and drastically cutting detection-to-correction time.

The chemical industry has always been complex and highly regulated, with teams tasked to record quality data and detailed health, safety, and environmental (HSE) metrics. Computer vision unlocks new data streams from your existing workflows. Combined with your other plant data, this visual intelligence supports preventive actions, faster root cause analysis, and more insightful reporting.

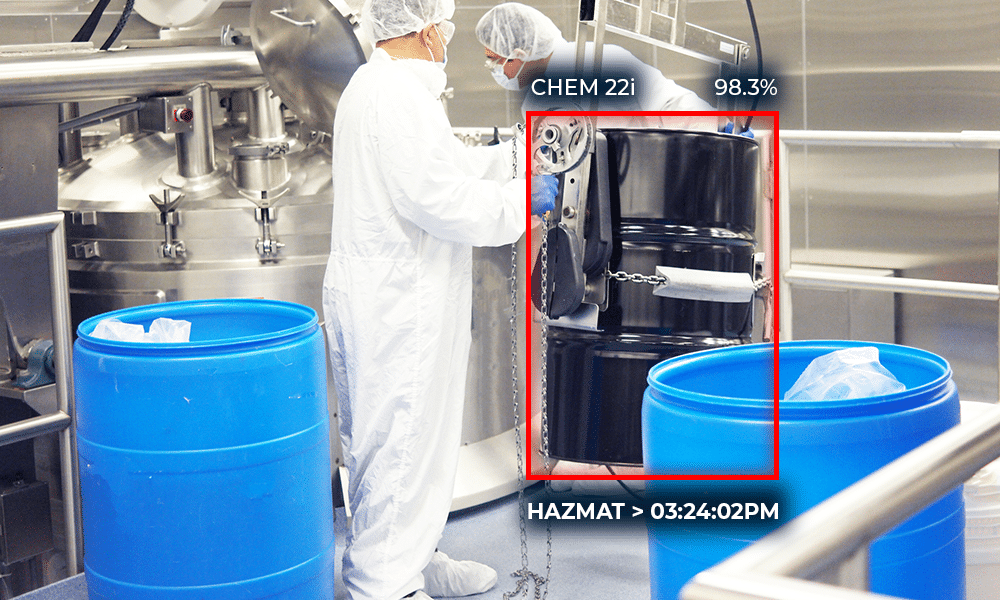

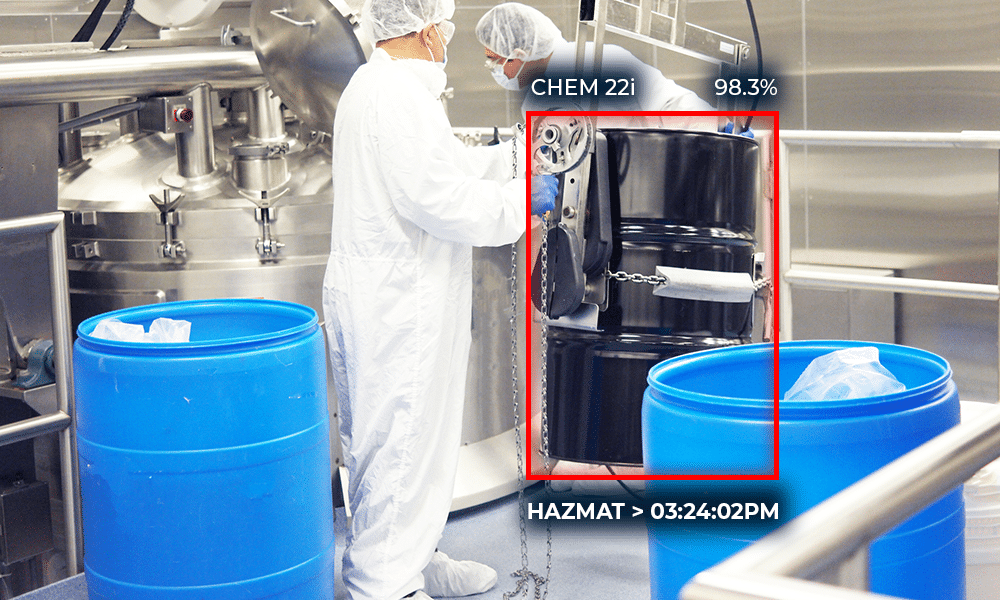

Boosting Safety and Consistency in Chemical Production

Safety is at the top of the compliance checklist for chemical processors. With hazards ranging from high-pressure vessels to hazardous fumes, even a small slip can become a major incident. Traditional HSE monitoring methods rely heavily on manual checks and after-the-fact reports, which leaves plenty of room for things to be missed.

However, when paired with new or existing cameras, computer vision can now analyze worker movements, spot breaches in safety protocols, or recognize loose personal protective equipment in real time. Employees get alerts before an incident happens, not after. Site managers can see actionable trends on heatmaps, pinpoint risk hotspots, and automate reporting for compliance.

Visual AI doesn’t just spot people in the wrong place at the wrong time. It also tracks operational parameters, ensures batches are within tolerance, and verifies that raw materials are handled correctly. It builds a safety net for process quality and worker well-being, reducing risk and simplifying audit trails.

Benefit from Surface Defect Detection

Surface quality, in particular, can make or break a product’s reputation in markets like paints, polymers, or advanced composites. While human inspectors are excellent at catching defects up close, they can fatigue, miss subtle inconsistencies, or be overwhelmed by scale.

Computer vision brings fatigue-free, impartial inspection to every stage of the materials production process. Modern vision systems, like those offered by Matroid, work independently of your camera type. They zoom in on anomalies that matter most—scratches, pits, bubbles, or color mismatches in coatings and films.

In the case of one Matroid client, a single employee was tasked with monitoring a 16-foot conveyor for 8 hours a day, 5 days a week. The inefficiency of one person looking for tiny defects on a sheet of vinyl flooring moving at 100 feet per minute cost the company nearly $2 million in returns yearly.

In addition to materials, industrial coatings can also benefit. An automated camera setup can scan every coated surface for micro-cracks or trapped particles that would later cause failure. If an issue crops up, the system can flag it instantly, trigger batch quarantines, or halt the line before more defective material is produced. This proactive approach slashes waste and rework costs and ensures that only high-purity, compliant products reach your customers.

Because these systems keep a digital record of every inspection, it’s also easier to build traceability into your processes for quality control and regulatory requirements.

Cleaner, More Consistent Outputs

The broader impact of computer vision is that it supports holistic process improvement across the plant. Every image captured is a data point woven into your operational analytics.

By feeding visual defect data into your manufacturing execution system or enterprise resource planning, you can identify trends early, predict the likelihood of future defects, and tweak upstream parameters for better yields. For example, recurring contamination alerts in a particular shift might flag an upstream equipment cleanliness issue. Over time, the result is fewer surprises, shorter troubleshooting cycles, and more reproducible, predictable output.

Powering Waste Reduction and Sustainability

It’s becoming impossible to separate operational efficiency from sustainability goals. The push for greener processes, fewer hazardous byproducts, and lower resource consumption is real from stakeholders and regulators alike.

Computer vision fits naturally in this landscape, helping plants hit compliance and environmental targets. Real-time defect detection means less material is scrapped, lowering the waste sent for disposal. By spotting contamination or off-grade batches sooner, fewer resources are wasted on reworking or recycling defective lots.

AI-fueled vision setups can also support predictive maintenance, catching signs of wear on equipment like mixers, extruders, or conveyors before they fail. This minimizes the risk of spills or environmental incidents while helping avoid unplanned shutdowns.

Visual AI also helps companies fine-tune their energy and resource use. If cameras recognize inefficient application patterns or material waste during transfer and handling, those insights can be routed to process engineers to adjust controls. The result is that over time, waste drops, yield rises, and overall sustainability improves.

Where conventional manual checks or periodic audits might have missed evolving problems, computer vision picks up issues immediately. The impact multiplies across plants with automated tracking and reporting, simplifying audits, meeting new ESG requirements, and giving transparency to all process stakeholders.

Moving from Defect Reaction to Defect Prevention

Easy integration with your existing plant cameras and systems means you can pilot vision projects quickly without new hardware or armies of programmers. Matroid offers a no-code solution, so your in-house engineers and quality experts lead in deploying and refining inspection routines. Over time, employees become more skilled with digital tools, and quality culture spreads to every corner of the plant.

If you’re measuring digital transformation by fewer defects, less rework, better compliance, and a smaller environmental footprint, then the ROI on computer vision is easy to justify. It’s less about replacing jobs and amplifying your team’s ability to identify issues, solve problems, and build better products at scale.

The manufacturing landscape is only getting more complex, which means problems are getting trickier, regulations are getting tighter, and the need for reliable, instant insights is greater than ever. AI-powered computer vision isn’t a silver bullet, but it does provide a smarter set of “eyes” across your entire operation.

For managers and quality leaders ready to modernize, the next step is simple: evaluate the trouble spots in your process where defects and waste creep in and pilot a computer vision project there. Sometimes, you can start with the cameras you already have to see what actionable data you get within a few weeks. From there, the benefits tend to compound, fueling a culture of continuous improvement.

If you’re ready for the next evolution in defect and waste reduction, computer vision could be your most valuable tool in pursuing safer, greener, and more competitive manufacturing. Reach out to a representative from Matroid to learn more.

Building Custom Computer Vision Models with Matroid

Dive into the world of personalized computer vision models with Matroid's comprehensive guide – click to download today