AI-Powered Quality Control for Electronics Manufacturing

Matroid | May 30th, 2025

Artificial Intelligence (AI) is no longer a futuristic speculation in manufacturing. Today, AI drives transformative changes, especially in the precision-driven domain of electronics manufacturing. From microchips to circuit boards, where even the tiniest flaw can compromise functionality, innovations in computer vision backed by AI are reshaping how the industry approaches production quality.

Electronics manufacturers are under immense pressure to deliver flawless products. Traditional quality control methods often fail to address demands for modern electronics production. Fortunately, Matroid’s proven expertise in computer vision is helping manufacturers meet the moment.

Save Time and Money by Detecting Defects Sooner

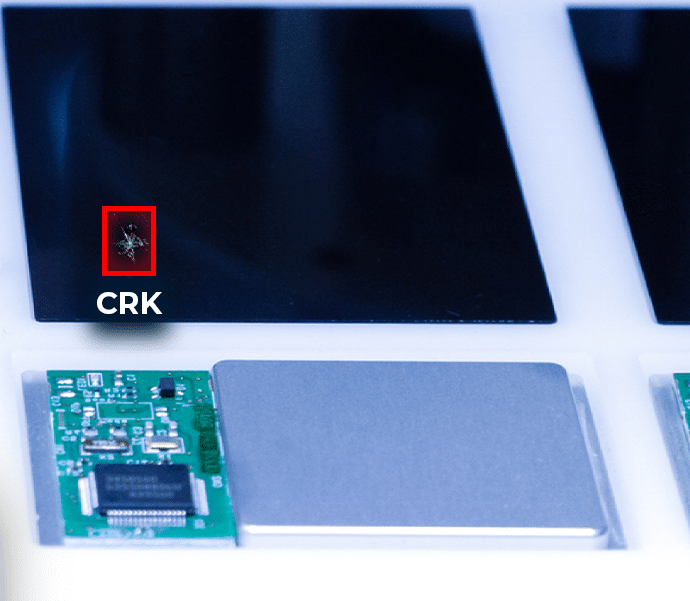

A key application of AI in electronics manufacturing lies in novel defect detection. Traditional quality control techniques like manual inspections or machine vision systems with pre-set rules struggle to meet today’s manufacturing demands. Human inspectors are prone to fatigue, resulting in errors, while rigid machine vision systems fail to adapt to new and complex manufacturing challenges.

Matroid’s AI-powered computer vision addresses these gaps. By leveraging advanced anomaly-detection capabilities, Matroid’s solution uses visual data and adaptive learning models to detect novel defects in real time. By leveraging this solution, potential design flaws or quality issues can be identified using only a handful of units during testing, eliminating the need for extra production runs or costly post-production inspection efforts.

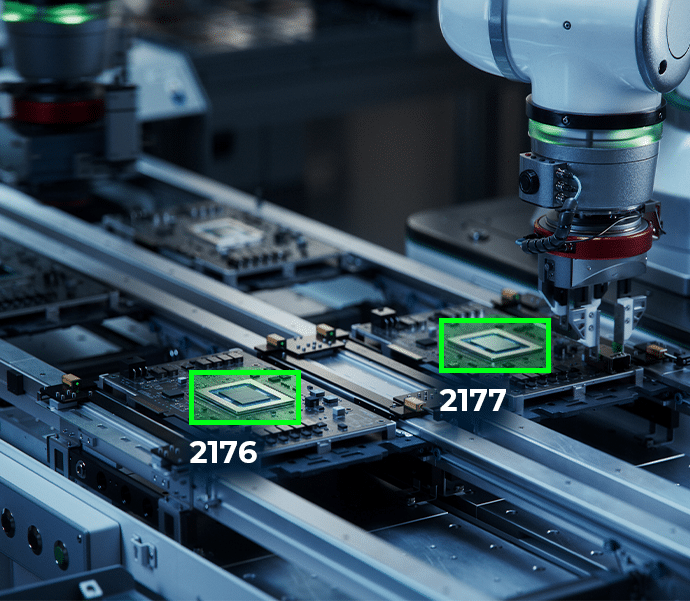

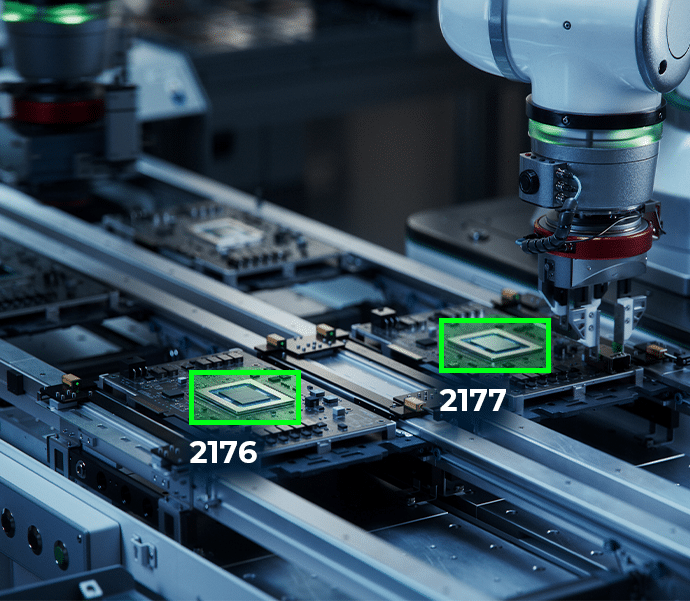

For example, in producing printed circuit boards (PCBs), identifying issues like soldering inconsistencies, hairline cracks, or missing components is critical. Traditional methods often result in false positives or leave defects undetected. Matroid’s approach is different. By intelligently analyzing data, it pinpoints irregularities accurately, refining detection capabilities as it gathers more insights.

Even the external finish of electronics can benefit from AI-driven inspection. Producers of appliances, laptops, and mobile devices can integrate computer vision to detect scratches, dents, or misaligned panels. High-resolution cameras supporting no-code AI programming can detect flaws and verify that products meet functional and aesthetic expectations.

Intercept and Address Known Defects

While finding new defects is vital, handling known defects is equally critical. Electronics production involves millions of small parts; even one oversight can disrupt a supply chain. Making matters more challenging, high-mix production environments demand solutions that can adapt to varying workflows without introducing inefficiencies.

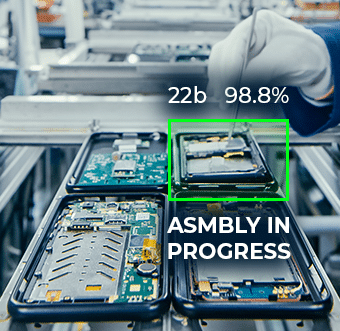

Matroid’s computer vision systems can augment the judgment of human inspectors by performing hundreds of visual inspections in seconds. Operators can rely less on manual oversight and more on automated precision. By verifying standard operating procedures in real time, Matroid ensures compliance with rigorous quality standards during production processes.

For example, a smartphone assembly line requires components such as connectors, chips, and screens to be assembled accurately. Matroid’s AI applications instantaneously validate the proper installation of components, catching errors like loose connections or misaligned parts before they reach the consumer.

Manufacturers can dramatically improve product quality and reduce costly reworks or repairs. Moreover, the system’s adaptability to various manufacturing settings makes it an ideal fit for facilities with diverse product portfolios.

Accelerate Failure Analysis

When a defect occurs, determining its root cause quickly and efficiently is paramount to maintaining seamless operations. Traditional failure analysis processes can be cumbersome, requiring extensive time and workforce to trace back issues and implement corrective actions.

Matroid’s AI-powered solutions drastically accelerate this process, saving up to 90% of the time typically spent on failure analysis. Matroid pinpoints potential root causes in minutes, not days, by aggregating production data and using AI to identify patterns.

The system’s anomaly-detection algorithms can sift through vast manufacturing datasets to isolate the underlying issue, whether a subtle material flaw or a calibration error in assembly equipment. Unlike older technologies that rely on rigid rules, Matroid’s adaptable AI learns from thousands of PCB images, refining its detection capabilities for dynamic environments.

Real-time insight accelerates remedial action and empowers manufacturers to eliminate recurring issues from future production runs. With less troubleshooting, companies can focus on innovation and efficiency instead of damage control.

Forging a Smarter, Safer Future

By gathering detailed cycle time data and analyzing production line performance, computer vision allows manufacturers to reap benefits beyond defect detection. Real-time alerts and automated monitoring facilitate quick corrective actions, safeguarding resources and profitability via reduced material waste, improved efficiency, and curtailed environmental impacts.

As technology evolves, electronics manufacturing will continue to undergo a dramatic transformation. Companies adopting Matroid’s solutions are in a position to set industry benchmarks in precision, scalability, and sustainability. By leveraging AI, they can optimize production processes, effectively balance cost efficiency with premium quality, and secure a competitive edge in evolving markets.

AI-powered quality control, implemented in partnership with Matroid, represents a paradigm shift in electronics manufacturing. It’s not just about improving efficiency—it’s about redefining how manufacturers set and achieve standards for excellence. Now more than ever, forward-thinking organizations must be prepared to integrate cutting-edge solutions.

If you’re interested in elevating precision, improving output quality, and reducing manufacturing risks, consider speaking with a member of the Matroid team. We can demonstrate how our technology can be seamlessly added into your production process to deliver results you and your customers can trust.

Building Custom Computer Vision Models with Matroid

Dive into the world of personalized computer vision models with Matroid's comprehensive guide – click to download today