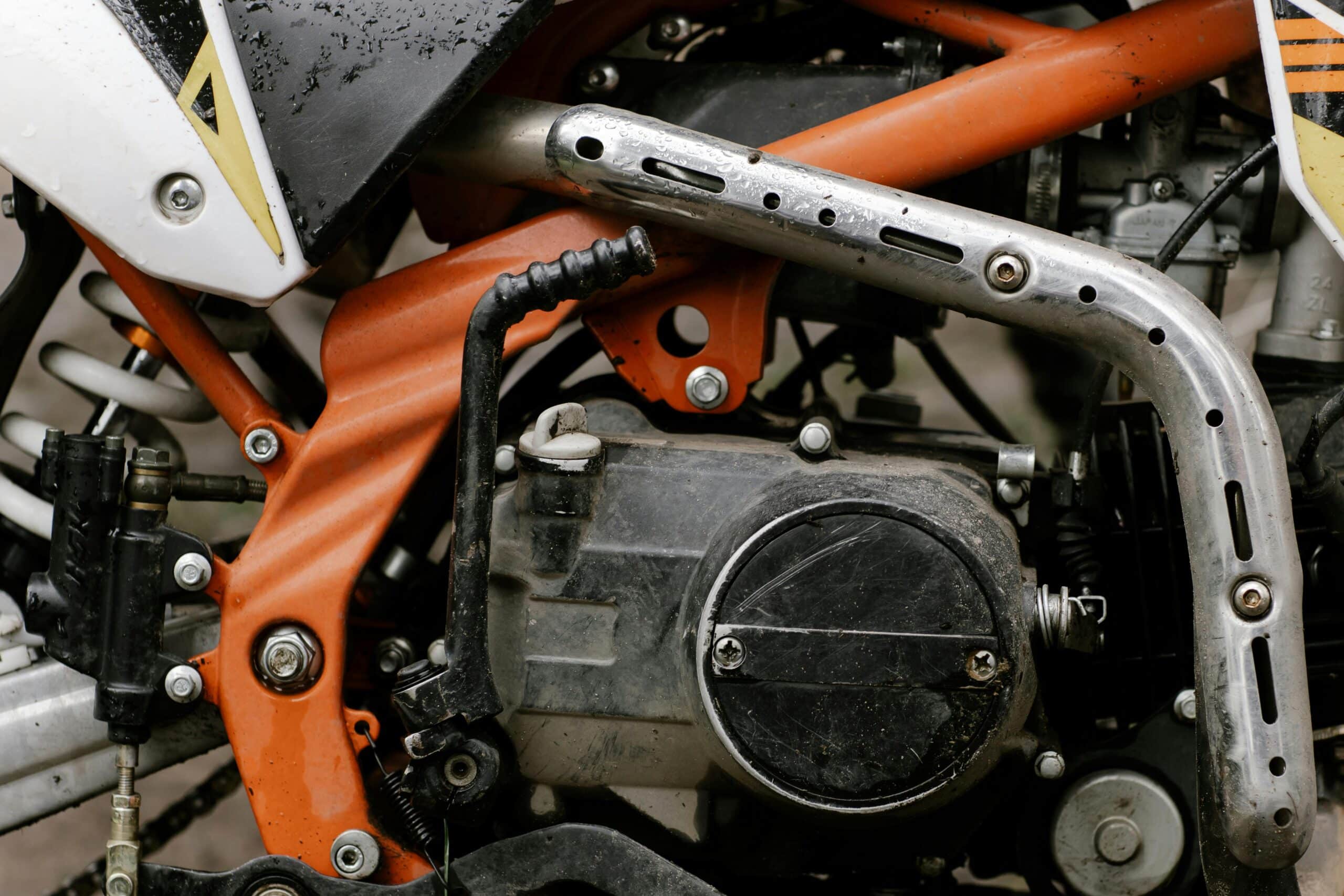

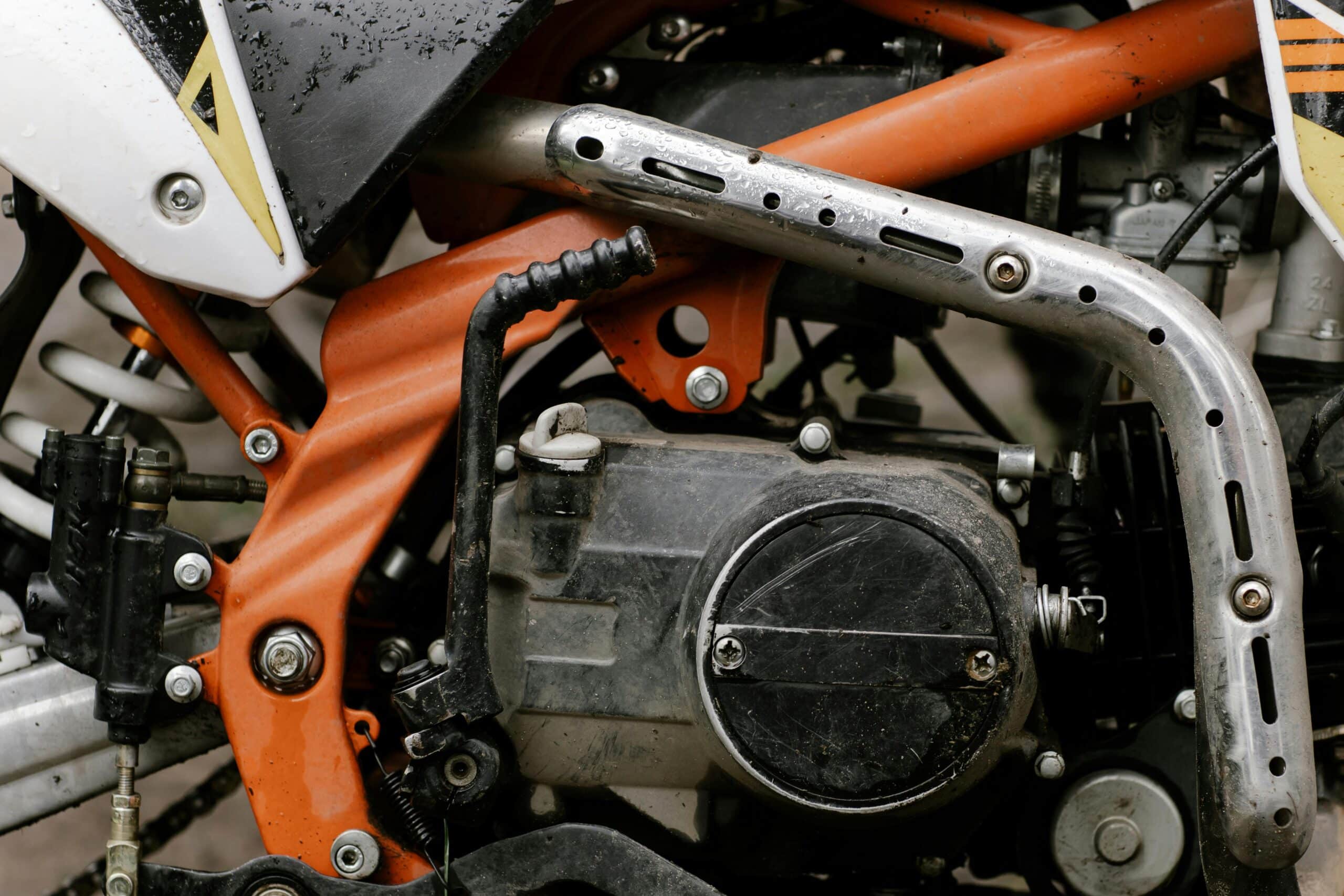

Why Defect Detection in Manufacturing is Critical for Automotive Production

Matroid | June 6th, 2025

Even the smallest imperfection can ripple through a production line, driving up costs, delaying shipment and harming a brand’s reputation. One misaligned component not only risks a costly recall but can dissolve consumer trust – in an industry where margins are already tight.

Thankfully, advanced systems like Matroid’s Computer Vision for Automotive Manufacturing help make sure that every part meets even the most exacting standards, greatly minimizing the likelihood that defects will slip through, especially with manual inspections.

Thanks to Matroid’s real-time, automated oversight, production lines can keep up the pace while being secure in the knowledge that blemishes, misalignments and other issues are greatly reduced as they continue to work toward a true zero-defect goal. Here’s how they do it:

Traditional Quality Control vs. AI-Driven Defect Detection

Traditionally, manual visual inspections and spot-check sampling have struggled to keep up with modern assembly methods. As parts become increasingly more interconnected and complex, they also become more prone to human error. Manual checks themselves are labor-intensive, inconsistent and prone to errors. Sampling can miss sporadic defects altogether which, if left unattended can cause reworks and warranty claims that cost the industry billions of dollars each year.

In comparison, AI-driven defect detection scales across every camera on the line, making sure that coverage is 100% without oversight or fatigue. Thanks to powerful solutions like Matroid’s end-to-end QA detection automating the process, it’s possible for systems to detect everything from sub-millimeter weld porosity to paint runs. Operators can be notified instantly in real-time to address the faulty processing as it happens and correct the flaw immediately.

What is Automated Visual Inspection?

Automated visual inspection or AVI is an advanced form of AI technology. With AVI, high-resolution cameras feed constant image streams into deep learning AI models that have been trained to spot even the slightest, most subtle deviations from the exact standards. These systems are able to operate at machine speed, meaning they can identify and inspect every unit without slowing down the line and causing bottlenecks.

Unlike traditional vision systems that rely on specialized hand-crafted algorithms and rigid thresholds, Matroids no-code AVI adapts to new types of defects on the fly. Hairline crack in a stamped panel? Plastic clip missing from a dashboard bezel? Its intuitive machine learning can recognize and alert to it, keeping manufacturers agile and competitive even as product designs evolve.

Why Choose Matroid for Defect Detection?

Matroid’s no-code platform excels across a number of critical automotive processes. For example, in welding stations, AI can inspect spot welds, MIG/TIG, laser and seam welds for everything from burn-through to porosity to spatter, misalignment and more, guaranteeing that the end result maintains its structural integrity before it heads down the line. During painting, the system can scan for drops, scratches and runs, making sure every body panel exists with a flawless finish.

With molding operations, it’s able to catch short shots, flash and missing clips on plastic components like bumpers and interior trims. This keeps assembly accurate while lessening cycle time. What’s more, Matroid offers an extensive library of pre-made detectors that are trained for these specific classes of defects, meaning that manufacturers can set up new inspections in minutes, not weeks, and all without writing a single line of code.

From Reactive Troubleshooting to Proactive Process Control

Whenever a defect is detected, whether it’s a misaligned powertrain mount or a contamination spot in a paint booth – the system instantly sends an alert to line operators and supervisors, who can then stop the flow of defective units while taking corrective steps to fix the issue. In short, AI isn’t replacing skilled technicians, rather it’s improving their capabilities by giving them even more superior “computer-aided vision” that never blinks and never tires.

Ongoing data collection and training also makes it possible to determine the root cause of an issue as well as recurring problems like material inconsistencies or tool wear that can lead to production stoppages or massive quality failures.

Real Life Use Cases Illustrate the Impact of Defect Detection

The business impact of having this kind of detailed, stringent defect detection is both instant and measurable. In the case of an aluminum extrusion process in metal stamping, AI-driven systems were able to reduce scrap rates by over 30% while weld inspection automation cut manual rework by 40%. With real-time alerts, downtime was minimized and assembly bottlenecks prevented, allowing for higher overall equipment effectiveness (OEE). Fewer defects mean fewer warranty claims and recall expenses, keeping profit margins and brand integrity high.

Scalable and Adaptable to Meet Today’s Challenges Head-On

In automotive production, scalability and adaptability are a must. Models, materials and volume shift and evolve frequently. Matroid’s platform provides cloud-friendly, hardware-agnostic architecture that integrates with your existing cameras and networks, making it possible to deploy the system across multiple production lines and plants. Engineers and quality managers can take advantage of its no-code interface to create, train and refine defect detectors in hours, not weeks or months (and without the need for data scientists!) With this level of just-in-time production, businesses can pivot to handle small batch runs and customization demands without the need for a massive outlay of inspection resources.

Working Toward Zero-Defect Manufacturing

The future looks even brighter and more profitable as Matroid works with top brands and manufacturers to continue toward a goal of zero-defect manufacturing. With integrative features like predictive maintenance and digital-twin frameworks, it’s becoming possible to blend ongoing vision data streams and IIoT (Industrial Internet of Things) sensors to forecast equipment breakdowns before they happen.

By closing the loop between detection, diagnosis and maintenance scheduling, manufacturers will soon be able to eliminate unplanned downtime while optimizing toward impressive levels of consistency and yield. Expect the future to include self-improving models, prescriptive analytics, and an even greater focus on quality, sustainability and competitiveness across the entire global automotive industry. Contact us today to learn more about our powerful no-code platform.

Building Custom Computer Vision Models with Matroid

Dive into the world of personalized computer vision models with Matroid's comprehensive guide – click to download today